Description

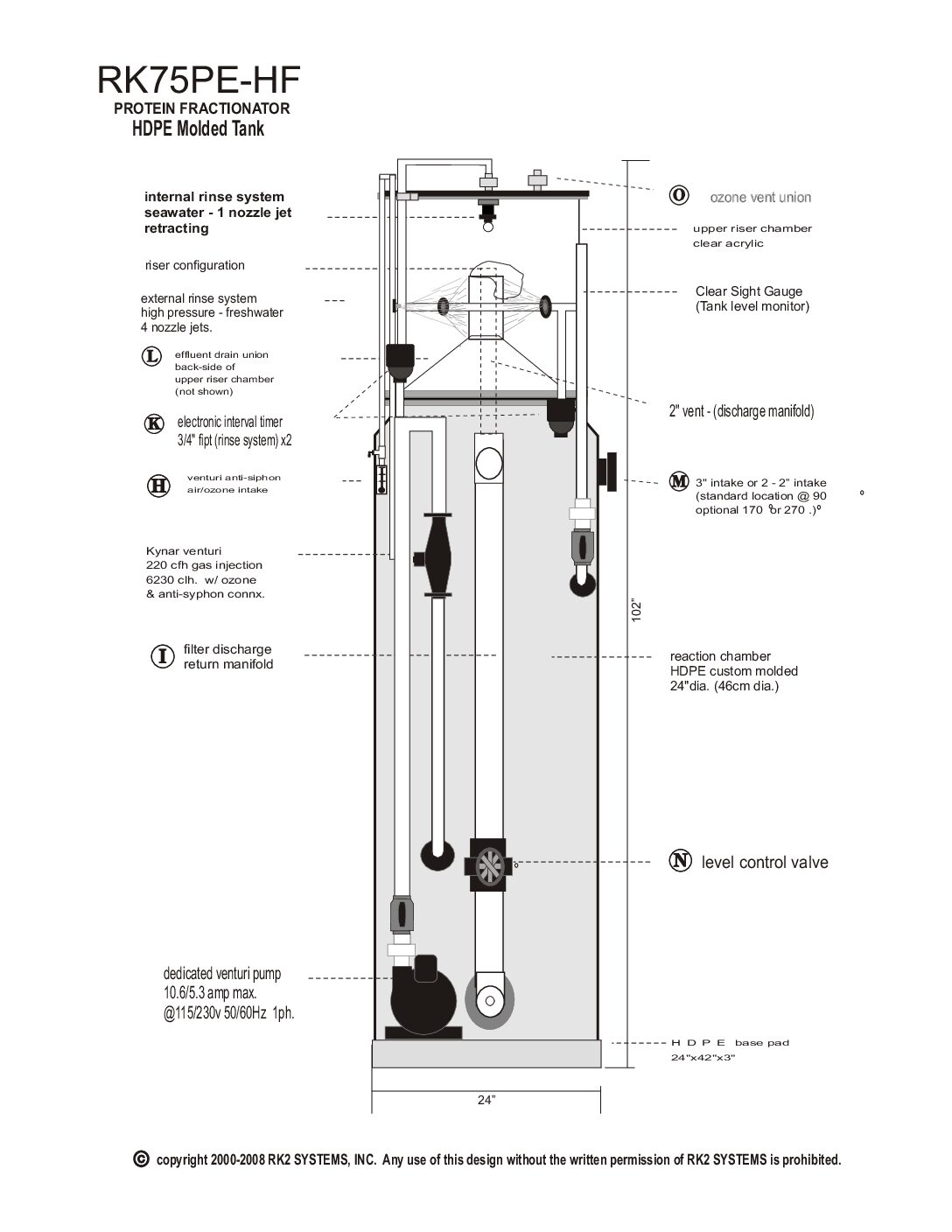

The RK75PE‑HF is a high-flow saltwater PE (polyethylene) protein fractionator designed for high-bioload, large-scale marine systems. This advanced foam fractionator efficiently removes dissolved organics, proteins, and fine particulates while increasing oxygenation and reducing microbial load.

Key Features

-

Counter-current foam fractionation: water enters from the top and air (or ozone) is injected at the base via a venturi injector.

-

One-piece, rotationally molded PE reaction chamber for maximum durability and leak resistance.

-

Integrated internal and external rinse system to prevent salt buildup and maintain skimmer performance.

-

Clear sight gauge for monitoring liquid and foam levels.

-

Screw-top lid for easy maintenance and access.

-

Industrial-grade Hayward or Asahi ball valves for reliable flow control.

-

Compatible with ozone systems through a dedicated injection port.

-

Includes a dedicated venturi pump for air/ozone draw.

Specifications

| Specification | Value |

|---|---|

| Flow Rate (High-Flow) | ~105–140 GPM (depending on contact time) |

| Reaction Chamber Diameter | 24 in (~61 cm) |

| Height | ~102 in (~259 cm) |

| Dry Weight | ~235 lb (~107 kg) |

| Operational Weight (Filled) | ~1,400 lb |

| Pump Model | 115/230V (1 ph) or 220V 50Hz |

| Rinse System | Internal seawater + external fresh‑water spray system |

Benefits

-

Greatly improves water clarity by removing dissolved organic waste

-

Boosts dissolved oxygen levels in the water

-

Reduces bacteria and pathogens through foam export

-

Supports high stocking densities in aquaculture and marine holding systems

-

Built for continuous, heavy-duty operation

Applications

-

Commercial marine aquaculture (recirculating systems)

-

Public aquariums and marine exhibits

-

Large reef or fish-only systems

-

Quarantine and broodstock facilities

-

Research and laboratory-based marine systems

Installation & Maintenance

-

Needs a feed pump and a venturi pump for air/ozone injection

-

Must be mounted on a sturdy base that supports its full weight when operational

-

Requires plumbing for inlet, outlet, rinse, and foam waste

-

If using ozone, connect your ozone generator to the venturi port

-

Regular maintenance: clean rinse nozzles, discard waste foam, check seals and O-rings, inspect venturi and valves

Why Choose the RK75PE‑HF?

If you need a durable and efficient fractionator for a high-volume, high-bioload saltwater system, the RK75PE‑HF is a top-tier choice. Its robust construction, ozone-ready design, and advanced cleaning capabilities make it well-suited for commercial aquaculture, large public aquariums, and research operations.

Technical Specifications — RK75PE‑HF

| Parameter | Specification |

|---|---|

| Model | RK75PE‑HF |

| Flow Rate | 105 GPM @ ~1.5 min dwell; up to 140 GPM @ ~1 min dwell |

| Reaction Chamber Diameter | 24 in (60.96 cm) |

| Height | ~102 in (≈ 259 cm) |

| Dry Weight | ~235 lb (≈ 107 kg) |

| Operational Weight (Filled) | ~1,400 lb (≈ 636 kg) RK2 |

| Venturi Pump Model | 45052.304 (115/230 V 1‑phase) or 45056.104 (220 V 50 Hz) |

| Material (Body) | One-piece rotationally molded Polyethylene (PE) |

| Venturi Injector Material | Kynar® (PVDF) |

| Rinse System | Internal wash-down + external rinse |

| Ozone Compatibility | Yes — designed for ozone injection |

| Contact Time Range | 1 – 1.5 minutes (for stated flow rates) |

| Base Footprint | 32 in × 44 in (≈ 81.3 cm × 111.8 cm) |

| Electrical / Power Consumption | ~5.75 A at 230 V (per spec sheet) |