Friction loss, plumbing design and pump selection in Aquaculture. A subject that often adds confusion and complexity to pump sizing, and if not calculated properly can cost you A LOT of money in running costs.

We have put together some examples of pump friction loss to demonstrate how useful this can be in saving you cold hard cash.

Before we begin, there are two costs involved in purchasing a pump:

THINGS YOU WILL CONTINUE TO PAY FOR AFTER YOU INSTALL A PUMP FOR ANY APPLICATION:

1. Maintenance on the pump (corrosion protection, seals, bearings)

2. Electricity to run the pump

THINGS YOU ONLY PAY FOR ONCE:

1. The pump

2. The plumbing

Keeping this in mind, lets move on to example 1.

Required flow – 450lpm

Vertical head – 2 meters

Pipe size 50mm

Pipe length 15 meters

Total calculated head 5.5 meters

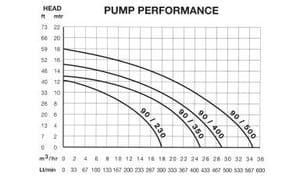

At 5.5 meters of head to get 450lpm or more, we would need to use a continental Speck 90/500 pump, with an energy use of 1100 watts. It is important to remember though, that there are a lot of pumps featuring better quality motors that are more efficient and use less energy, and with specially designed impellers.

MORE EFFICIENT PUMP SELECTION

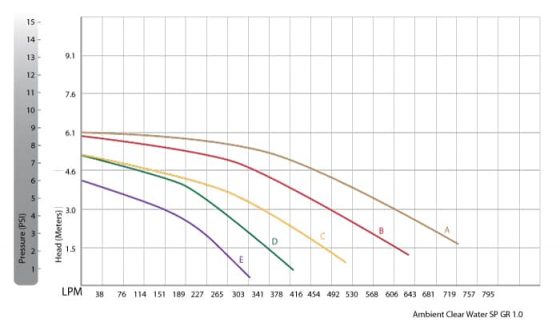

Looking for a more efficient pump option, the RK2 Low RPM Superpro pumps could achieve just under this flow with a 1/3HP RK2 Superpro with an energy use of 400 watts. Or an increased flow (potentially up to 500LPM) with the 1/2HP RK2 SuperPro pump and use only 600 watts, Utilising 80mm pipe.

Compared to using the Speck 90/500, you can achieve an energy saving of between 500 to 700 watts, if using RK2 SuperPro Low RPM pumps, and not a swimming pool style pump.

Using a base energy cost per kWh of 20 cents, you could save $2.40 per day up to $3.36 per day. Over a year this is between $876 and $1226.40

| MOTOR | PART NUMBER | ENCLOSURE | RPM | CURVE |

|---|---|---|---|---|

| 3/4 HP | 43076.114 LH | TEFC | 1425 | A |

| 1/2 HP | 43056.114 LH | TEFC | 1425 | B |

| 1/3 HP | 43036.114 LH | TEFC | 1425 | C |

| 1/4 HP | 43026.114 LH | TEFC | 1425 | D |

| 1/8 HP | 43016.114 LH | TEFC | 1425 | E |

PRICES OF THE PUMPS:

90/500 $807

1/3HP Low RPM Superpro $1732

1/2HP Low RPM Superpro $1817

With the minimum energy savings you are looking at a return on investment of 14 months, with the maximum energy savings you are looking at a ROI of 10.6 months.

Careful attention and preliminary design to target optimum friction loss, plumbing design and pump selection in Aquaculture systems provides huge benefits long term, even in the relative short term. After a worst case scenario of 14 months a minimum of $876 a year is back in your pocket for 1 pump.

How many pumps are you running in your facility?