Biological filter media, and the Biological filtration system they are used in, is the heart of any filtration system for Aquaculture or wastewater.

Pure Aquatics can size a variety of biological filters including:

Not all filter media is created equally, and there are many very important key design and operational parameters that need to be met, for both the media and the biological filter reactor vessel as well.

For instance, are you looking to boost your MBBR’s filtration capacity? Have a look at the Hel-X flake

The design of MBBR Biofilter media elements is only one part of the story in an MBBR filter, or any biofilter for that matter. Other factors such as dwell time, hydraulic loading rate, air and water distribution, media velocity and oxygen transfer all determine overall effectiveness and removal rate of nitrogeous waste. There is a lot more involved in designing any biofilter than just throwing in media and aerating it, and this especially true of an MBBR. Pure Aquatics have identified specific removal rates for our media the K+ and HEL-X FLAKE, and have optimised its performance through identifying design parameters in biofilter design. Although surface area plays a role in removal rates in MBBR’s, it isn’t all that is involved.

Please do not hesitate to contact us with your MBBR or other biofilter requirements.

Plastic media, for use in biological Pond filters – specifically in moving bed bio reactors, was pioneered by Evolution Aqua, some 20 years ago. In recent years, other plastic media have come onto the market, usually with the aim of trying to get more and more surface area. However, one drawback to using plastic media has always been the time it takes to establish a stable biofilm – essential for good filtration.

After many years of research, Evolution Aqua have now developed a new media that not only gives class leading surface area, but also overcomes the problem of long maturation times.

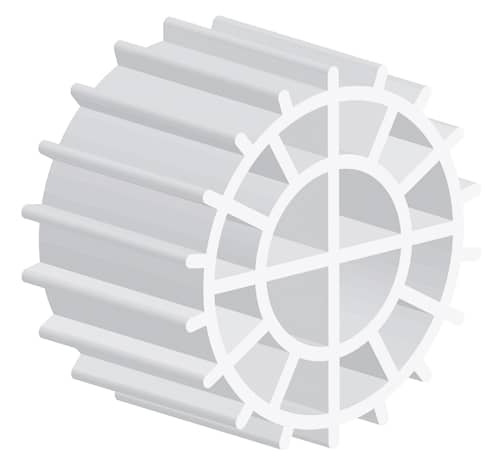

K+Media is designed and manufactured in the UK by Evolution Aqua. This advanced media, with its innovative design, and class leading surface area provides enhanced biological and mechanical filtration. As Evolution Aqua extrude the K+Media, Minerals and Enzymes are added to the raw material. The result of this process, unique to Evolution Aqua, is a filtration media that not only outperforms most of its competitors due to its large protected surface area, but also answers the problem of how to speed up the time taken to mature your filter.

To boost your MBBR’s performance, why not also consider the addition of HEL-X FLAKE?

NOW IN 30MM AND HIGHER SURFACE AREA!!

SURFACE AREA 5,500M2/M3

SIZE 30MM X 1MM

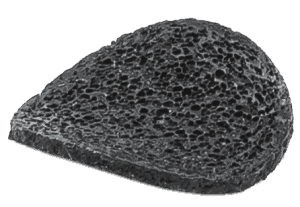

Hel-X medias are a powerhouse in MBBR carrier design, from conventional style carrier elements to trickle filter media and the incredibly high surface area FLAKE, there is a media for every application.

The HEL-X FLAKE boasts a improved surface area of over 5,500m2/m3, with higher TAN removal than ever before.

The HEL-X company was the first company to develop this type of media carrier and has invested significant time and resources into research of their flake product, resulting in a cost effective but equally impressive removal performance compared to other high surface area biomedia types.

Pore size, circulation, biofilter design and overall substrate concentration and diffusion across the biofilms determine the removal rates in the system, and this goes hand in hand with surface area. The volume of surface area and pore distribution within and one the carrier element is only one part of the equation, too much porosity, size of pores and not enough cleaning of the media can negatively impact waste removal in some cases.

HEL-X FLAKE can be used solely in a biofilter, or, as we prefer to use the media, as a mix in certain ratios to boost biofilter removals and result in lower effluent concentrations.

As most MBBR’s in Aquaculture are only filled to 50% void volume, HEL-X FLAKE can be deployed to fill the further 10% of the reactor volume (totalling 60%) to boost biofilter TAN removal.

HEL-X FLAKE is available in either a black re-granulate (recycled) product, or a virgin (white) HDPE.

Pure Aquatics represent HEL-X in Australia and New Zealand and distribute on demand other carrier element types from HEL-X should you have a specific requirement.

Trickle filter degassing media can come in many different shapes and sizes.

A balance between design, packing configuration, water and gas mixing, surface area and void space is important to the overall performance of trickle filter media.

For biological filtration, trickle filter degassing media with a good void ratio with the highest possible surface area is desired to result in the best gas exchange, oxygenation and nitrification mix. Biological filters that use the trickle tower/trickle filter design simultaneously degas CO2, oxygenate water, and convert ammonia to nitrite to nitrate.

For CO2 degassing, a high void space should be the main concern with media design to reduce waste buildup, maximise water flow and optimise gas movement.

In both applications air is commonly force counter current to the water flow to maximise the gas exchange inside the filter or degassing unit.

Degassing units are commonly applied following biological filters such as moving bed biofilters

BIOLOGICAL TRICKLE FILTER MEDIA

HIGH WASTE LOAD DEGASSING MEDIA

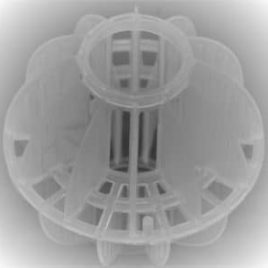

Do not dismiss the power and efficiency of a trickle filter. As long as attention is paid to gas exchange inside the filter, and water distribution, the trickle filter is incredibly efficient as TAN removal and simultaneous degassing. Degassing is very important in RAS systems for removal of CO2 and other dissolved gases, it is even more important when using submerged filters like Fluid bed sand filters and MBBR’s. Trickle filters have a wide loading range in both water flow and TAN removal, as TAN levels increase so does TAN removal and so can be very well suited to shock loaded systems.

Trickle filter media can come in various shapes and sizes, commonly pinned bioballs or a variety of other carbonate-based medias have been used. Pure Aquatics’ Degassing Bio Balls have a higher surface area per m3 and feature a sufficient void space to allow for simultaneous degassing. The bladed shape of the balls allows for sufficient shearing of biofilms that get too thick and help to prevent mulm build up by eliminating the small spaces often present in pinned bioball designs. As with all biofilter designs, sufficient pre-filtration and removal of solid waste will improve removal rates. For assistance with sizing and design of trickle filters please contact us and we would be happy to assess your application. Degassing rings are an established design of degassing media with a high void space and gas exchange capability for the removal of dissolved gases in waste streams.

Degassing rings are often used where high flows and high solids loads are present. Due to their high Void space, open design and lower surface area, they are more resistant to blocking and therefore stay cleaner for longer. They also do not have as high of a pressure drop and therefore more air can be forced through them (either actively or passively) resulting in better gas exchange.

Predominantly used for degassing, with a small capacity for nitrification, degassing rings are a great option for dissolved gas removal where biological filtration is not the primary concern, or biological filtration is already adequately sized within the system.

| Product | Size (approx) | SSA m2/m3 | Void Space |

|---|---|---|---|

| Degassing Bio Balls 25mm | 25mmD | 460 | 84% |

| Degassing Bio Balls 38mm | 38mmD | 325 | 87% |

| Degassing rings 25mm | 25mm x 25mm | 175 | 90% |

| Degassing rings 38mm | 38mm x38mm | 155 | 89% |