Pure Aquatics supply a range of continuous monitoring systems for monitoring of system parameters, eg: pH, kH, Dissolved Oxygen (DO).

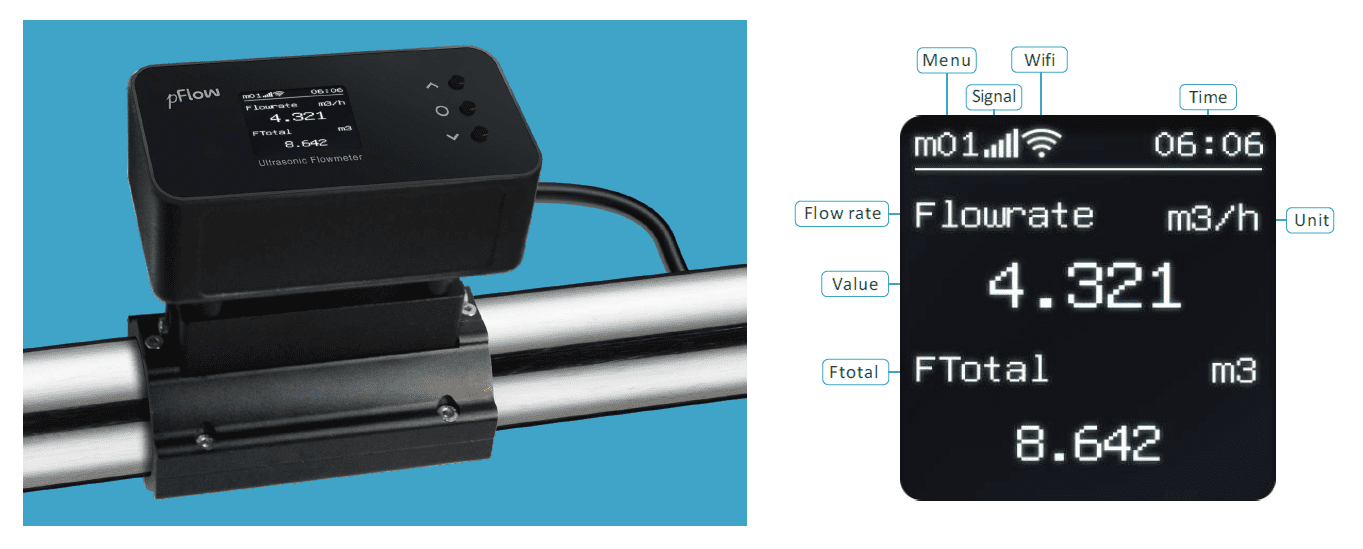

Ultrasonic flow meters are changing the way we measure flow and are a quick and easy solution to flow monitoring that can be added at almost any point within a system.

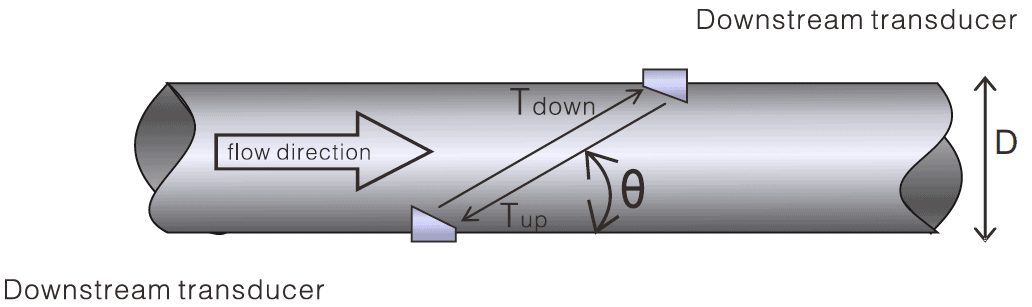

Ultrasonic flow meters use a signal transmitted through the liquid from one sensor to another. When the ultrasonic signal is transmitted and received through the moving liquid, there will be a difference between the upstream and downstream transit time, which is then used to calculate flow and velocity.

The F3 ultrasonic clamp on flow meter is a lightweight, compact easy to install flow meter.

The D116 clamp-on ultrasonic flowmeter offers non-contacting measurement with uncomplicated mounting and minimum maintenance. The flowmeter can be installed and seamlessly integrated without intervention in the piping system.

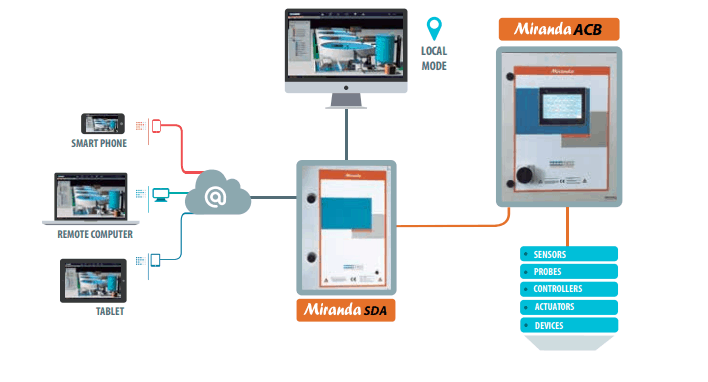

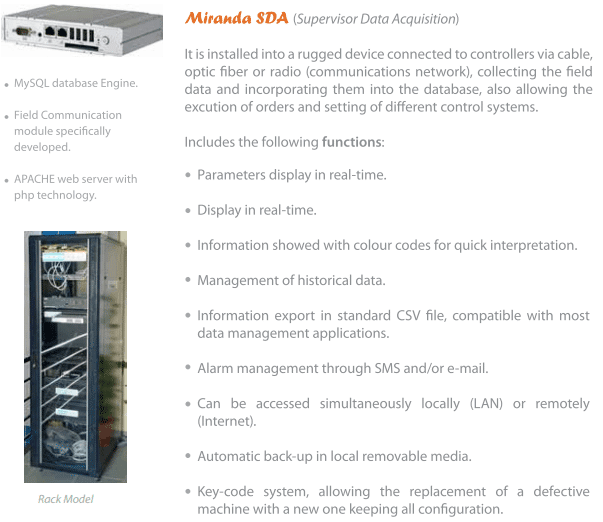

Robust and reliable monitoring systems for producers, managers and researchers allowing you to monitor and control parameters in real- time, on site or remotely.

Save time and money by optimising your operations. Create the reports you need to manage your installation better and take the right decisions timely.

Innovaqua has many years of experience and knowledge and has designed several specific control modules for aquaculture such as photoperiod, thermoperiod or feeding management (Mirafeed) that are fully integrated.

Pure Aquatics now have a pH/ORP Monitor and Controller that is built to withstand the harsh environments of Aquaculture systems. The Pure Aquatics pH/ORP Monitor is easy to operate and comes pre-wired to suit your control requirements.

Perfect for use with our range of ozone generators, or your choice of ozone generator or pH control system.

pH Monitoring and Control

Monitoring and control of pH produces a more stable environment for not only the culture species but also the nitrifying bacteria in an aquaculture system.

Nitrifying bacteria not only have an optimum pH range (7-8.5 depending on species) but they also utilise the inorganic carbon in the form of carbonate and bi-carbonate from the alkalinity reserve in your water as part of their metabolism.

Without optimum pH, and the inorganic carbon source as part of their metabolic requirements, nitrifying bacteria can become inefficient and with a complete lack of carbonates, pH crashes, nitryfing bacteria die and the biofilter crashes, in some cases leading to catastrophic results.

Manual dosing can be utilised very effectively, whoever using a pH monitor/controller to automatically dose a saturated alkalinity solution to control pH (and kH by proxy) the control of pH in a culture system can produce much more stable results and more stable culture conditions.

ORP Monitoring and control

ORP monitoring and control is commonly used when using ozone generators.

ORP, which is measured in mV (millivolts) when used to measure water quality can be loosely described as an indicator of the cleanliness and quality of your water. The lower the mV rating the lower the water quality, and the higher the mV reading the higher the water quality (and higher the level of oxidants in the water).

It is highly recommended that an ORP controller be used when using ozone as a water quality control solution. ORP can be useful even in systems where ORP is not used as it gives the operator an indication of water quality and can be utilised as another data point in determining water quality and culture conditions.

YSI Water quality monitors offer the best in monitoring and data acquisition. YSI provide a complete range of handheld monitors, continuous monitors and benchtop water quality analysis options for your monitoring needs.

Pure Aquatics continue to work with YSI monitoring products as we have done for over 15 years. We trust that YSI offer superior products for our customers monitoring needs, and we continue to utilise YSI’s quality monitoring solutions, support and technology for this reason.

YSI continue to be a leader in the supply of continuous monitor/controllers. The YSI 5200A, 5400 and 5500D family of monitors provide solutions for continuous monitoring and control for your entire facility.

The YSI continuous monitors can be controlled and data viewed at the monitor, via Aquamanager software and now on the all new Aquaviewer 2 app.

With YSI’s wide range of expansion models and inbuilt features (such as the feedsmart technology) automation, control, data acquisition and alarming are now available in one package that is easily linked together in a variety of combinations to suit almost any application.

It has never been easier to monitor and control your water quality than it is with the YSI Continuous recirculating Monitors.

With YSI’s recent development of the Aquaviewer 2 App remote monitoring and alarming is now at your fingertips.

Monitoring and controlling with the 5200A, 5400, and 5500D is managed locally by the instrument, not at a central PC or PLC. This provides security that an entire system won’t fail.

Easy to use with low cost of ownership. User-scalable as your facility changes, unlike typical PLCs or DCPs. No engineers or programmers needed to change or add to the system.

With the ability to measure virtually any parameter using a variety of probes at multiple locations, you can design a total facility solution.

Feed Smart™ conditional feed timer software is included with every monitor. Very powerful feeding capabilities interface with most powered feeders.

With AquaManager®, you will have access to quality data (water quality parameters, event logs, etc.) to better manage your operation and improve efficiency. SMS and email alarms quickly notify if parameters exceed user-defined limits. Data can be easily accessed remotely using AquaManager.

Mix and match monitor and control instruments as well as expansion modules for flexibility in designing a system to best meet facility needs.

Ensuring a successful and sustainable aquaculture business with environmentally friendly practices begins with an accurate and reliable understanding of water quality parameters. Without an accurate understanding of growth conditions, “crop” health can suffer and improper feeding habits may be used, ultimately resulting in disappointing production levels, high input costs, water pollution and even disease. YSI Continuous recirculating Monitors help you to maintain control of your farming operations.

YSI has all the tools necessary to effectively monitor and manage your aquaculture operation. YSI’s spot sampling handheld water quality instruments allow for a quick check of water conditions, while our continuous multi-parameter and DO monitors can aid in process control for your entire facility. YSI monitors can assist with your operation’s feeding cycle via our Feed Smart™ timer and aid in the overall management of your facility with the facility mapper included with AquaManager software. AquaManager also allows you to easily view real-time water quality conditions remotely via PC or through the AquaViewer app. Additionally, alarms can be set when conditions fall below user-defined standards, quickly alerting facility management of the condition so they can respond quickly to the change in conditions.

YSI 5200A Multiparamater monitor is engineered specifically for recirculating aquaculture systems, the YSI 5200A continuous monitor and AquaManager® Software can be used to integrate process control, feeding, alarming, and data management into one product or can be used to simply monitor one tank. Powerful enough to manage a full scale farming operation from anywhere in the world yet simple enough for anyone to use.

Access your facilities water quality data at any time with the AquaViewer App from the App Store or manage your network with AquaManager desktop software.

Feed Smart software manages food delivery based on user-selectable inputs to manage feed delivery based on number of daily feedings, daily feed weights, total biomass and FCRs, along with parameter control based on water quality values. interfaces with most auto feeders.

AquaManager desktop software provides the ability to instantly see an overview of your facility, manage parameter set points, and conveniently manage data to make informed operation decisions. If you’re interested in a continuous monitor for dissolved oxygen, please visit the 5500D (optical dissolved oxygen) or 5400 (galvanic dissolved oxygen) page.

The YSI IOEM and REM expansion modules increase the flexibility and capability of the YSI aquaculture platform when networked with 5200A, 5400 or 5500D instruments. Configure 4 (IOEM-4) or 8 (IOEM-8) analogue channels as inputs or outputs for the ability to integrate 3rd party sensors or output from other devices. Outputs can be configured to control pumps, UV systems, analogue valves, or send data to SCADA/ PLC systems. REMs (Relay Expansion Module) add relays where needed to control feeders, lighting, heaters, alarming, and more.

The YSI 5400 DO monitor is engineered specifically for aquaculture systems, the YSI 5400 DO monitor and AquaManager® Software integrate process control, alarming, and data management into one product. Simple enough to monitor one tank, powerful enough to manage a full scale farming operation from anywhere in the world. Simultaneously measure dissolved oxygen in multiple tanks or ponds.

Access your facilities water quality data at any time with the AquaViewer App from the App Store or manage your network with AquaManager desktop software.

Feed Smart software manages food delivery based on user-selectable inputs to manage feed delivery based on number of daily feedings, daily feed weights, total biomass and FCRs, along with parameter control based on water quality values. interfaces with most auto feeders.

AquaManager desktop software provides the ability to instantly see an overview of your facility, manage parameter set points, and conveniently manage data to make informed operation decisions.

If you’re interested in a continuous monitor for multiple parameters, please visit the 5200A page or if you’d prefer optical dissolved oxygen please visit the 5500D page.

The YSI IOEM and REM expansion modules increase the flexibility and capability of the YSI aquaculture platform when networked with 5200A, 5400 or 5500D instruments. Configure 4 (IOEM-4) or 8 (IOEM-8) analogue channels as inputs or outputs for the ability to integrate 3rd party sensors or output from other devices. Outputs can be configured to control pumps, UV systems, analogue valves, or send data to SCADA/ PLC systems. REMs (Relay Expansion Module) add relays where needed to control feeders, lighting, heaters, alarming, and more.

5500D monitors and their optical probes proved to be a valuable tool for the management of super-intensive shrimp culture, allowing quick adjustments to be made to minimize stress from low DO while setting upper and lower DO limits helped to optimize oxygen use.

– Dr. Tzachi Samocha

Designed specifically for aquaculture systems, the YSI 5500D continuous monitor for dissolved oxygen and AquaManager® Software can be used to integrate process control, feeding, alarming and data management into one product or can be used to simply monitor one tank. With YSI’s ODO® optical dissolved oxygen technology you’ll benefit from reduced costs, less maintenance and better data. The ODO sensors require no membrane changes, no electrode cleaning, no stirring requirement and less frequent calibrations.

Access your facilities water quality data at any time with the AquaViewer App from the App Store or manage your network with AquaManager desktop software.

The standard conditional feed timer, Feed Smart, manages food delivery based on user’s preset criteria. Manage feed delivery based on user-selectable inputs for the number of daily feedings, daily feed weights, total biomass and feed conversion ratios (FCRs), along with parameter control based on water quality values. Interfaces with most auto feeders.

Optional AquaManager® desktop software allows you to view, configure, or setup instruments from the convenience of one central location. Instantly see an overview of your facility, manage parameter set points, and conveniently manage data to make informed operational decisions. The facility mapping feature provides an immediate overview of all ponds or tanks indicating their current state.

The YSI IOEM and REM expansion modules increase the flexibility and capability of the YSI aquaculture platform when networked with 5200A, 5400 or 5500D instruments. Configure 4 (IOEM-4) or 8 (IOEM-8) analogue channels as inputs or outputs for the ability to integrate 3rd party sensors or output from other devices. Outputs can be configured to control pumps, UV systems, analogue valves, or send data to SCADA/ PLC systems. REMs (Relay Expansion Module) add relays where needed to control feeders, lighting, heaters, alarming, and more.