Aquaculture biosecurity is paramount to a successful aquaculture facility. Two reliable and effective biosecurity measure for both disinfection and water quality control are Ultraviolet (UV) sterilisation, and ozone.

UV Sterilisers can be applied in a variety of configurations to treat a wide range of flow rates and to target specific organisms from algae and bacteria to protozoans and viruses.

The application of ozone can be applied to control water quality on an ongoing basis in an aquaculture system, removing BOD, colour, TSS and bacteria and improving water quality and filtration performance, or can be used in higher concentrations to sterilise water to make it safe for introduction into your facility.

Pure Aquatics has the experience and sizing criteria to assist with designing and applying UV steriliser and Ozone systems for biosecurity measures and water quality control.

THE NEXT EVOLUTION OF UV STERILIZER

Pure Aquatics offers RK2 Systems UV Steriliser’s to suit any application.

Xflo UV sterilizers come in sizes from 18 watt to 300watt utilizing low pressure high output T5 lamps.

Pro-Tect UV Sterilizers range in size from 160 watt to 2560 watt utilizing low pressure amalgam (ALH/AUH) and high output (HLH/HUH) UV lamps.

One of the primary jobs the sales and marketing team at RK2 and Pure Aquatics with relation to UltraViolet (UV) water treatment systems-is customer education. ‘Why is that?’ you may ask. Unfortunately, while the concept of UV treatment appears simple, the actual application of the technology is anything but. In fact, capable OEM suppliers take great care to ensure that the customer is able to meet their actual treatment needs, in all practical operational scenarios, today, and as the system ages.

In many cases a potential customer may notice that one quote for a UV product may come in at a significantly higher cost than that of another. Good news, right? Lowest bid wins!

Well, perhaps the company that provided the lowest bid wins, but the real loser may be the customer. In the UV treatment industry, as in many others, it is the hidden or unknown factors that can greatly impact whether your system actually delivers the intended UV dose, or ‘treatment’, or not. In fact, UV water treatment is such a complex technology that the USEPA and other regulatory bodies worldwide have standardized sizing and application regulations for municipal drinking water and waste water.

While aquaculture does not abide by regulations per se (there are regulated aquaculture applications in some countries), capable OEM suppliers use these regulations as guidelines to ensure that the customer has the treatment they require when they purchased their UV system-to ensure adequate protection of their investments at all times.

fort a reliable and accurate sizing, contact RK2 and Pure Aquatics for sizing of RK2 Systems UV Steriliser’s.

RK2 XFLO UV STERILIZERS – PROFESSIONAL GRADE EQUIPMENT FOR THE HOME AQUARIST AND POND ENTHUSIAST

Introducing a new option in UV Sterilization.

Looking for a better and more reliable UV option for your backyard pond, water feature, or home aquarium? RK2 is proud to offer our new RK2 XFLO UV Steriliser. Our design team has a combined 60+ years experience and we meticulously worked to create the most user friendly UV solution available while ensuring users a technically sound product they can trust to get the job done right. Whether choosing our RK2 XFLO UV Steriliser with our standard output, three inch diameter model, or our high output five inch diameter model, XFLO UV has the best solution for your specific needs.

Each mirco-organism has its own UV dose or “kill rate”. Determining what micro-organism you are trying to apply UV sterilization to is key to how successful you will be in using a UV Sterilizer. The dose the UV sterilizer will produce is determined by the water flow rate through the steriliser body and across a specific UV lamp. Accurate information from the manufacturer is a must when operating any UV steriliser.

| XFLO Model | Wattage | NO. Lamps/Watts | Dia | Length | Inlet/Outlet | Flowrate (30mj/cm2) | Flowrate (180mJ/cm2) | Rec’d Aquarium Size* (Lt.) | Rec’d Pond Size** (Lt.) |

|---|---|---|---|---|---|---|---|---|---|

| XFL3-18L | 18 | (1) 18 | 80mm | 530mm | 40mm | 900 LPH | 135 LPH | 150 | 3,800 |

| XFL3-25L | 25 | (1) 25 | 80mm | 810mm | 40mm | 1800 LPH | 230 LPH | 230 | 7,600 |

| XFL3-40L | 40 | (1) 40 | 80mm | 1192mm | 40mm | 3,850 LPH | 630 LPH | 560 | 17,000 |

| * = Aquarium Size based on 180mJ/cm Flow rates and 1 turnover per hour |

| **= Pond Size Based on 30mJ/cm2 Flow rates and 1 Turnover every 3-4 Hours |

XFL3-40L

| XFLO Model | Wattage | NO. Lamps/Watts | Dia | Length | Inlet/Outlet | Flowrate (30mj/cm2) | Flowrate (180mJ/cm2) | Rec’d Aquarium Size* (Lt.) | Rec’d Pond Size** (Lt.) |

|---|---|---|---|---|---|---|---|---|---|

| XFL5-50H | 50 | (1) 50 | 127mm | 890mm | 2 | 5600 LPH | 900 LPH | 900 | 22,500 |

| XFL5-80H | 80 | (1) 80 | 127mm | 1270mm | 2 | 10,200 LPH | 1590 LPH | 1500 | 38,000 |

| XFL5-120H | 120 | (1) 120 | 127mm | 1580mm | 2 | 14,500 LPH | 2270 LPH | 2250 | 53,000 |

| XFL5-150H | 150 | (1) 150 | 127mm | 2000mm | 2 | 22,500 LPH | 3860 LPH | 3800 | 75,500 |

| * = Aquarium Size based on 180mJ/cm Flow rates and 1 turnover per hour |

| **= Pond Size Based on 30mJ/cm2 Flow rates and 1 Turnover every 3-4 Hours |

XFL5-80H

| Model | Wattage | NO. Lamps/Watts | Dia | Length | Inlet/Outlet | Flowrate (30mj/cm2) | Flowrate (180mJ/cm2) | Rec’d Aquarium Size* (Lt.) | Rec’d Pond Size** (Lt.) |

|---|---|---|---|---|---|---|---|---|---|

| XFL6-100ML | 100 | (2) 50 | 153mm | 890mm | 80mm | 9760 LPH | 1,590 LPH | 1500 | 8,000 |

| XFL6-160ML | 160 | (2) 80 | 153mm | 1264mm | 80mm | 18,400 LPH | 3,180 LPH | 3,400 | 17,000 |

| XFL6-240ML | 240 | (2) 120 | 153mm | 1585mm | 80mm | 24,980 LPH | 4,090 LPH | 4,200 | 22,000 |

| XFL6-300ML | 300 | (2) 150 | 153mm | 1943mm | 80mm | 39,370 LPH | 6,585 LPH | 6,800 | 36,000 |

| * = Aquarium Size based on 180mJ/cm Flow rates and 1 turnover per hour |

| **= Pond Size Based on 30mJ/cm2 Flow rates and 1 Turnover every 3-4 Hours |

XFL6-300ML

RK2 PRO-TECT ULTRAVIOLET STERILISERS: AFFORDABLE, PRACTICAL SOLUTIONS

Introducing RK2 Pro-Tect Ultraviolet sterilisers. All Pro-Tect UV systems feature durable, non-corrosive schedule 80 PVC reaction chambers. Each system utilizes single end glassware assemblies which simplify maintenance and reduce over all labour costs associated with operating a UV system. Our inlet/outlet ports are engineered to ensure optimal hydraulic mixing inside the reaction chamber.

RK2 Pro-Tect Ultraviolet sterilisers feature power supply enclosures that are made using non-metal, non-corrosive thermoplastic or fiberglass. Our standard HMI (Human Machine Interface) control package is user friendly and simplifies daily operation. A colour touch screen display shows basic operating status of the UV system and alerts users to any problems that may arise. Upgrading to the optional HMI Pro series control package expands the capabilities of your Pro-Tect UV system. HMI Pro series control package offers a larger colour touch screen display and more advanced monitoring options. Both the standard HMI and optional HMI Pro series packages include water temperature monitor with alarm and safety cut off switch.

With a combined 50+ years of UV experience, consider a Pro-Tect UV system for your applications.

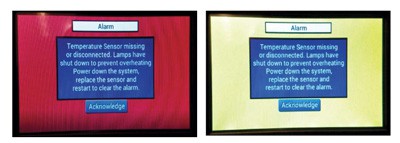

ALARM MODE FLASHES RED/YELLOW

STANDARD HMI PACKAGE INCLUDES:

HMI PRO SERIES PACKAGE INCLUDES:

SINGLE END LAMP AND SLEEVE ACCESS

LAMP STATUS SCREEN

Corona Discharge Ozone Generators are among the most efficient and reliable form of ozone generator.

Ozone needs to be generated on site and requires energy to do so, and Corona discharge ozone generators do this more efficiently than other form of ozone generation.

Activated oxygen, ozone or O3, is a naturally occurring substance, it is generated when lightning strikes. It is a practical solution for many industries aiming to reduce the use of hazardous chemicals and exposing staff to chemical fumes.

Research reveals that ozone kills bacteria and viruses far more effectively and cost effective than chlorine and produces no disinfection byproducts (DBP’s).

Ozone is a useful water quality control agent, moves into water 13 times easier than oxygen, and reverts to oxygen after it reaction. It oxidises solid and dissolved wastes on contact that effect water clarity and colour in RAS, and in sterilisation applications, can kill bacteria, fungi, parasites and viruses.

Ozone also assists other filtration to perform better, it helps to microfloculate particles in water so mechanical filters work more effectively. It reduces waste buildup on biological filters and reduces BOD so biofilters work more effectively, and through clarifying and clearing water, UV sterilisers have better penetration through the water column resulting in higher sterilisation rates.

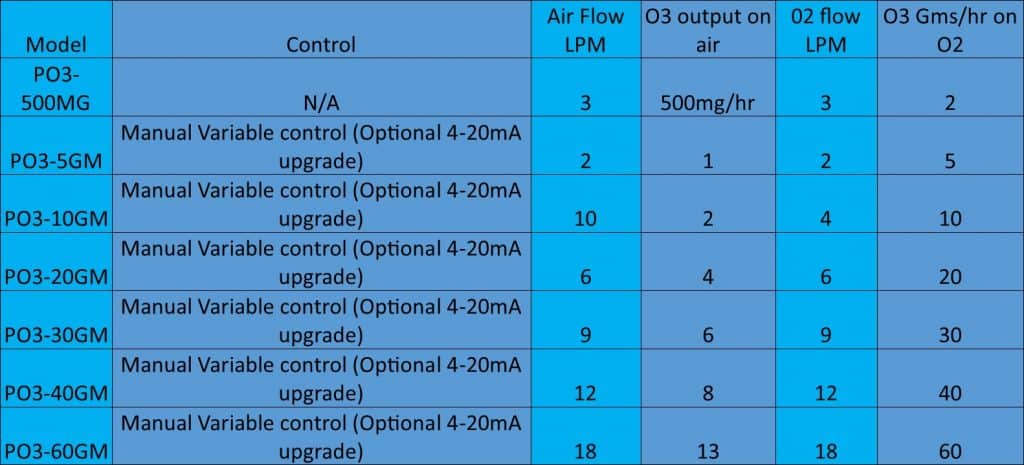

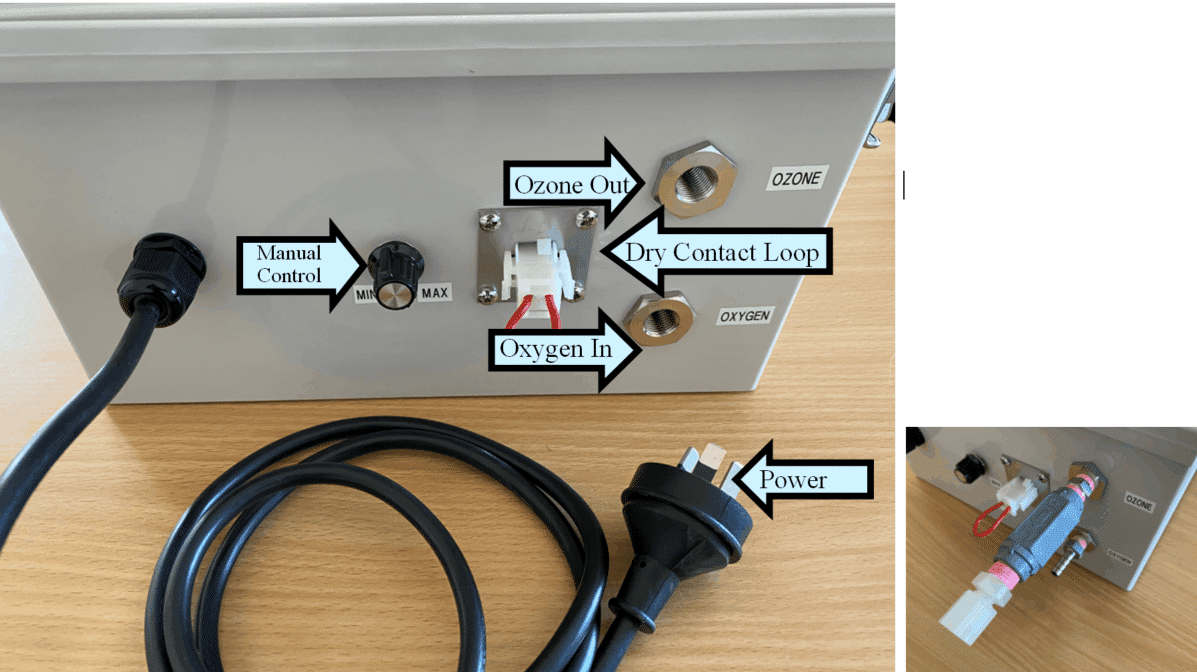

Pure O3 – the ultimate in ozone generator design for harsh aquaculture environments!

In an effort to produce equipment more suitable for harsh aquaculture environments, Pure Aquatics have developed the Pure O3 line of ozone generators.

Our humid and sometime salt laden environments can play havoc with electronics, and high voltage ozone generators can be susceptible to damage/corrosion to their electronics, and at the very least their enclosures corrode and rust.

The Pure O3 ozone generator design features stainless steel connections and a plastic enclosure, offering the ultimate in corrosion resistance. For ozone generators that are not placed in a plant room, additional attachments for ducting the air suction supply for the circulation fans are available.

Ozone Solutions ozone generators are corona discharge ozone generators integrating the latest technology and research and development.

Ozone (O3) is a form is oxygen (O2) that consists of three oxygen atoms. When ozone comes in contact with contaminants, such as bacteria and pathogens, it causes an oxidation reaction that eliminates the contaminants, and breaks the ozone down into two oxygen molecules. This reaction is what makes ozone a safe and effective disinfectant.

For over 100 years, ozone generation has been used as a disinfectant in many industries, such as food production, water treatment, and many more. Over time, ozone generation has shown that it is an improvement to many processes that conventionally use harsh chemicals as disinfectants. This is because of the extreme cost savings, and the many health benefits of using ozone in place of chemicals, such as chlorine.

Ozone Solutions Inc., founded in 1997, is a full-service provider of cost-effective and environmentally friendly technology. Our products and services are internationally present in many different industries and applications. We are reaching out to our customers through our global network of distributors as well as our regional sales and manufacturing representatives in North America. Today, Ozone Solutions Inc. is moving forward in company and product development, in order to become the most trusted and innovative supplier of environmentally friendly technology.

Since 1965, Hess Machine International has been the bottled water industry’s leading supplier of ozone purification systems. That leadership is the result of having both the highest quality equipment and the individualized service that meets each customer’s specific requirements. Our system’s superior patented design assures consistent, reliable transfer of ozone into the water. It is designed for easy installation, operation and maintenance. This gives you the confidence you need in a cost-effective way.