RK2 Systems Protein Fractionators (also called foam fractionators or protein skimmers) are a proven technology that is applied to remove suspended and dissolved wastes that other conventional filtration devices cannot remove.

Foam Fractionation or Protein Skimming is the removal of proteins, dissolved organics, and total suspended solids from water. Unlike other forms of mechanical filtration that only trap debris and waste, Foam Fractionation or Protein Skimming, actually removes or strips it from the water.

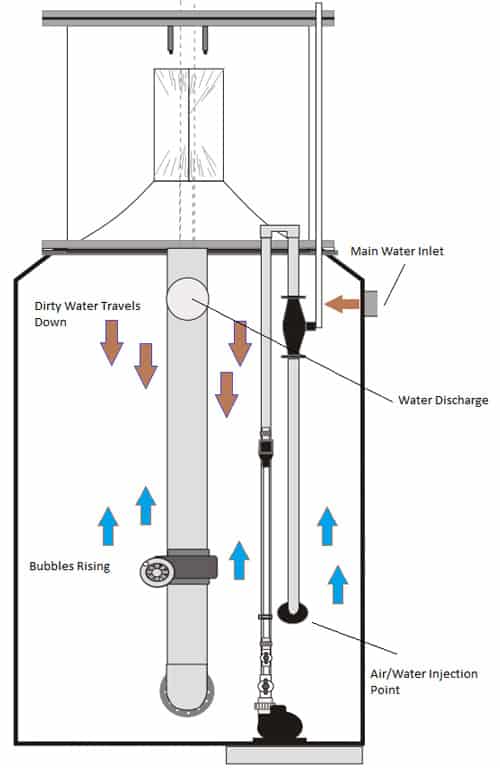

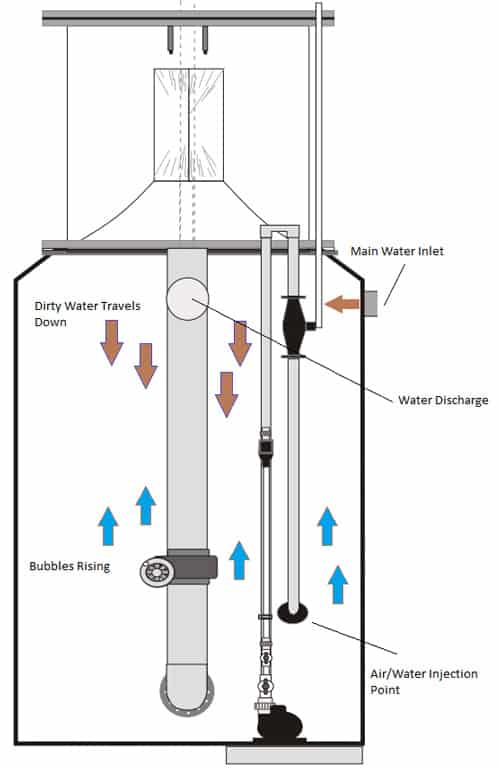

This process is carried out inside of a Foam Fractionator or Protein Skimmer by injecting air, in the form of tiny bubbles, through a column of water creating an air to water interface. In general, the smaller the bubbles the more effective the foam fractionation or protein skimming process is. This is because smaller bubbles have more surface area while occupying the same volume of water as larger bubbles. This mixture of air and water is injected towards the bottom of the Foam Fractionator or Protein Skimmer and allowed to travel up through the incoming organic laden water. Due to the natural charges of these organic molecules, they are either repelled or attracted to the air/water interface. These molecules can be described as hydrophobic. Large numbers of small bubbles present an enormous air/water interface for molecules to collect on the bubble surface (the air/water interface). This process continues until the bubbles increase near the top of the water column inside the foam fractionator or protein skimmer, they become denser and the water begins to drain and create the foam that will carry the organic molecules to the waste collection cup and the organic molecules will be exported from the water.

Whilst removing waste RK2 Systems Protein Fractionators simultaneously oxygenate the water, degas CO2 and can act as an injection point for ozone.

RK2 Saltwater Protein Fractionators (also called foam fractionators or protein skimmers) are filtration devices that remove suspended particulates, dissolved organics, proteins and tints. At the same time, protein fractionation lowers bacteria and pathogen concentrations, while saturating the water with oxygen. Traditional water filtration systems, (i.e: pressurized sand filters, bead filters and cartridge filters), remove particulates but are ineffective against dissolved wastes and act as breeding grounds for bacteria and pathogens.

Water that is filtered through traditional filters is constantly sieved through the trapped wastes. Similar to that of a tea bag, this action leaches bacteria, dissolved organics and tints back into the water. The media in the filter functions as a bio-filter, promoting bacteria, which in turn strip out oxygen. Consequently, the discharge from these filters is generally enriched with bacteria and dissolved organics as well as having reduced oxygen concentration.

When using RK2 Saltwater Protein Fractionators, the fractionation filtration process is simple and highly effective. Air, (in some cases ozone as well), are injected into the bottom of the reaction chamber via an ozone resistant venturi injector. The water to be filtered is introduced at the top of the chamber and exits at the bottom. This creates a mass mixing effect, with the water traveling cross current to the air, which is essential for the effective formation of foam. The foam rises through the column and becomes more concentrated as it passes into the upper rise tube. The tube allows for the water to drain back into the tank via gravity, while the concentrated foam is ejected over the top of the riser tube and collected into a waste drain. The upper chamber is automatically washed down with rinse systems that keep the surfaces clean and prevent the foam from drying and inhibiting the ejection process.

Ozone Injection enhances the fractionation process in a number of ways. Ozone oxidizes various pathogens, from bacteria to viruses. Ozone is extremely effective on organic water tints creating crystal clear water. Ozone also breaks down the structure of larger organic molecules, which facilitates their removal by fractionation. Being a three-part oxygen molecule, ozone dramatically increases oxygen concentration. Ozone in doses appropriate for aquaculture is very safe.

The fractionation and ozone combination is extremely effective in a variety of applications. Grow out tanks and aquaria displays with heavy bio-loads become remarkably cleaner. Clean Systems, such as larval rearing or holding tanks can become crystal clear. Protein fractionation with ozone is excellent for systems with heavy mucous concentrations such as closed or semi open finfish and shellfish holding systems. Other applications include purging systems, grow out systems, effluent treatment as well as influent water treatment for use within partial and full flow thru systems.

The protein fractionation process increases water clarity and oxygen concentration, and also destroys and removes pathogens. Consequently, appetite, stocking densities, feed and growth rates are all enhanced and animal health improved.

Used within aquaculture, live seafood holding as well as most public aquariums worldwide, RK2 Saltwater Protein Fractionators are an essential component within any aquatic life support filtration system. Protein fractionation is effective in seawater, freshwater as well as brackish water systems, within partial or full flow applications. Individual models are available with processing flow rates from 3 to 2000 gallons per minute. For larger flow rate applications, our protein fractionators can be incorporated into any modular system design, thus allowing us to process any system volume where protein fractionation is required.

| Model | Flow Rate | Diameter | Venturi pump | Height | Footprint | Operational weight | Dry Weight |

|---|---|---|---|---|---|---|---|

| RK10AC | 35-75 LPM | 25.4 CM | 1/6 HP PUMP | 230 VAC, 1 PH | 215.9 CM | 38.1 X 91.44 CM | 124.73 KG | 45.35 KG |

| RK25PE | 76-133 LPM | 35.56 CM | 1/6 HP PUMP | 230 VAC, 1 PH | 195.58 CM | 60.96 X 91.44 CM | 200 KG | 47 KG |

| RK50PE | 152-228 LPM | 50.8 CM | 1/2 HP PUMP | 230VAC, 1 PH | 251.46 CM | 81.28 X 86.36 CM | 477 KG | 100 KG |

| RK75PE | 265-398 LPM | 60.96 CM | 1 HP PUMP | 230 VAC, 1 PH | 259.08 CM | 81.28 X 86.36 CM | 636 KG | 107 KG |

| RK75PE-HF | 398-530 LPM | 60.96 CM | 1.5 HP PUMP | 230 VAC, 1 PH | 259.08 CM | 81.28 X 86.36 CM | 636 KG | 107 KG |

| RK150PE | 587-871 LPM | 91.44 CM | 1.5 HP PUMP | 230 VAC, 1 PH | 256.54 CM | 104.14 X137.16 CM | 1352 KG | 166 KG |

| RK150PE-HF | 871-1,174 LPM | 91.44 CM | 1.5 HP PUMP | 230 VAC, 1 PH | 256.54 CM | 104.14 X 137.16 CM | 1352 KG | 166 KG |

| RK300PE | 1,098-1,647 LPM | 121.92 CM | 1.5 HP PUMP | 230 VAC, 1 PH | 279.40 CM | 137.60 X 167.64 CM | 2305 KG | 200 KG |

| RK300PE-HF | 1,647-2,196 LPM | 121.92 CM | 2 HP PUMP | 230 VAC, 1 PH | 279.40 CM | 137.60 X 167.64 CM | 2305 KG | 200 KG |

| RK600PE | 3,370-4,505 LPM | 152.4 CM | (2) 1.5 HP PUMPS | 230 VAC, 1 PH | 365.76 CM | 175.26 X 198.12 CM | 4847 KG | 341 KG |

| RK600PE-HF | 3,370-4,505 LPM | 152.4 CM | (2) 2 HP PUMPS | 230 VAC, 1 PH | 365.76 CM | 175.26 X 198.12 CM | 4847 KG | 341 KG |

| RK1000PE | 4,164-6,246 LPM | 213.96 CM | (4) 1.5 HP PUMPS | 230 VAC, 1 PH | 365.76 CM | 233.68 X 289.56CM | 9242 KG | 409 KG |

| RK2000PE | 5,679-7,571 LPM | 213.96 CM | (4) 2 HP PUMPS | 230 VAC, 1 PH | 426.72 CM | 238.76 X 289.56 CM | 11,585 KG | 545 KG |

* = HF models operate at higher flow rates and reduced contact times.

**Pro Series Models are available at an additional cost. Pro Series includes – schedule 80 PVC plumbing, Hayward True Union Ball Valves, Electronic Wash Down Assemblies and bulkhead fittings.

RK2 Freshwater Foam Fractionators are the original and still the most effective fractionator for protein and TSS removal in freshwater.

In freshwater the process of protein fractionation is used widely in the wastewater treatment industry (referred to as dissolved air flotation). Freshwater Foam Fractionators for Aquaculture applications have been pioneered and refined by RK2 with their development of the RK2 Freshwater Foam Fractionators. While the bubbles are larger in freshwater than in saltwater, RK2 have designed and refined their designs to achieve maximum effectiveness of protein fractionators in freshwater.

The addition of Ozone into a freshwater fractionator add a vector for ozone to be introduced as well as helping to stabilise the protein fractionator and oxidise and flocculate waste into particles that are more easily removed by the protein fractionation process.

Protein Fractionation filtration removes suspended particulates, dissolved organics, proteins and tints. At the same time, protein fractionation lowers bacteria and pathogen concentrations, while saturating the water with oxygen. Traditional water filtration systems, (i.e- pressurized sand filters, bead filters and cartridge filters), remove particulates but are ineffective against dissolved wastes and act as breeding grounds for bacteria and pathogens.

We have spent significant time developing and refining our protein fractionator designs to be able to offer you the most effective freshwater protein fractionator system available.

Water that is filtered through traditional filters is constantly sieved through the trapped wastes. Similar to that of a tea bag, this action leaches bacteria, dissolved organics and tints back into the water. The media in the filter functions as a bio-filter, promoting bacteria, which in turn strip out oxygen. Consequently, the discharge from these filters is generally enriched with bacteria and dissolved organics as well as having reduced oxygen concentration.

The fractionation filtration process is simple and highly effective. Air, (in some cases ozone as well), are injected into the bottom of the reaction chamber via an ozone resistant venturi injector. The water to be filtered is introduced at the top of the chamber and exits at the bottom. This creates a mass mixing effect, with the water traveling cross current to the air, which is essential for the effective formation of foam. The foam rises through the column and becomes more concentrated as it passes into the upper rise tube. The tube allows for the water to drain back into the tank via gravity, while the concentrated foam is ejected over the top of the riser tube and collected into a waste drain. The upper chamber is automatically washed down with rinse systems that keep the surfaces clean and prevent the foam from drying and inhibiting the ejection process.

| Model | Flow rate | Diameter | Venturi Pump | Height | Footprint | Operational Weight | Dry Weight |

|---|---|---|---|---|---|---|---|

| RK10AC-FW | 35-75 LPM | 25.4 CM | 1/2 HP PUMP | 230 VAC, 1 PH | 215.9 CM | 38.1 X 91.44 CM | 124.73 KG | 45.35 KG |

| RK25PE-FW | 76-133 LPM | 35.56 CM | 1/2 HP PUMP | 230 VAC, 1 PH | 195.58 CM | 61.0 X91.44 CM | 200 KG | 47 KG |

| RK50PE-FW | 152-228 LPM | 50.8 CM | 1 HP PUMP | 230VAC, 1 PH | 251.46 CM | 81.28 X 86.36 CM | 477 KG | 100 KG |

| RK75PE-FW | 265-398 LPM | 60.96 CM | 1.5 HP PUMP | 230 VAC, 1 PH | 259.08 CM | 81.28 X 86.36 CM | 636 KG | 107 KG |

| RK75PE-HF-FW | 398-530 LPM | 60.96 CM | 1.5 HP PUMP | 230 VAC, 1 PH | 259.08 CM | 81.28 X 86.36 CM | 636 KG | 107 KG |

| RK150PE-FW | 587-871 LPM | 91.44 CM | 1.5 HP PUMP | 230 VAC, 1 PH | 256.54 CM | 104.14 X 137.16 CM | 1,352 KG | 166 KG |

| RK150PE-HF-FW | 871-1174 LPM | 91.44 CM | 1.5 HP PUMP | 230 VAC, 1 PH | 256.54 CM | 104.14 X 137.16 CM | 1,352 KG | 166 KG |

| RK300PE-FW | 1098-1647 LPM | 121.92 CM | 2 HP PUMP | 230 VAC, 1 PH | 279.4 CM | 137.60 X 167.64 CM | 2,305 KG | 200 KG |

| RK300PE-HF-FW | 1647-2196 LPM | 121.92 CM | 2 HP PUMP | 230 VAC, 1 PH | 279.4 CM | 137.60 X 167.64 CM | 2,305 KG | 200 KG |

| RK600PE-FW | 2215-3370 LPM | 152.4 CM | (2) 2 HP PUMPS | 230 VAC, 1 PH | 365.76 CM | 175.26 X 198.12 CM | 4847 KG | 341 KG |

| RK600PE-HF-FW | 3370-4505 LPM | 152.4 CM | (2) 2 HP PUMPS | 230 VAC, 1 PH | 365.76 CM | 175.26 X 198.12 CM | 4847 KG | 341 KG |

| RK1000PE-FW | 4164-6246 LPM | 213.96 CM | (4) 2 HP PUMPS | 230 VAC, 1 PH | 365.76 CM | 233.68 X 289.56 CM | 9242 KG | 409 KG |

| RK2000PE-FW | 5679-7571 LPM | 213.96 CM | (4) 2 HP PUMPS | 230 VAC, 1 PH | 426.72 CM | 233.68 X 289.56 CM | 11,585 KG | 545 KG |

* = HF models operate at higher flow rates and reduced contact times

**Pro Series Models are available at an additional cost. Pro Series includes – schedule 80 PVC plumbing, Asahi True Union Ball Valves, Electronic Wash Down Assemblies and bulkhead fittings

Meet the newest models of RK2’s commercial foam fractionator lineup! Our AC series is designed for low flow rate applications while keeping the performance and quality that larger RK2 models have become known for. RK2’s nearly 30 years of engineering experience combined with the extensive R&D we are proud to offer a truly commercial grade foam fractionator for aquarium professionals, home hobbyists and aquaculture professionals alike. These units are built to withstand the most demanding applications. We utilize a design that is based on proven science and volume metrics to bring you the best performing fractionators available today.

All RK2 fractionators utilize counter current design. This means incoming (dirty) water enters high on the reaction chamber or vessel. The incoming water then travels downward through the rising air, which is injected low inside the reaction chamber, before exiting the bottom of the reaction chamber. In comparison, a co-current designed model has it’s incoming water and air/water mixture entering at the same level inside the foam fractionator. Once inside the fractionator, both the incoming water and air/water mixture travel in the same direction, which offers little to no mixing and operates with a much shorter contact/dwell time.

The AC series is made from the highest quality materials available. The moulded bases are made from High Density Polyethylene (HDPE) that doesn’t require gluing or bonding to fabricate. The reaction chamber is made from a single section of acrylic tube. The riser cone, collection cup, and collection cup lid are made from nearly non-breakable polycarbonate material and our Mazzei Air Injector (Venturi model only) is made from highly durable ozone resistant Kynar. This guarantees it will not break down when exposed to ozone.

When coupled with the recommended L1/L2 Vectra pumps, our foam fractionators operate at approximately 1amp of power at 12VAC. Simply put, there is no reason to look anywhere else for your foam fractionator needs! Whether you are a hobbyist in need of a fractionator for your larger display tanks or an industry professional in the aquaculture or public exhibit sectors, the AC series fractionator by RK2 is your answer!

| RK2 Systems Model | Operating Flow Rate | Diameter | Base Dimensions | Height | System Capacity |

|---|---|---|---|---|---|

| RK5AC | 19-38LPM | 25.4cm | 30.5×30.5cm | 122cm | 3785-7570L |

| RK8AC | 49-98LPM | 25.4cm | 30.5×30.5cm | 152.5cm | 7570-15,140L |

| RK10AC | 57-114LPH | 25.4cm | 46×91.5cm | 195.5cm | 9460-22,710L |

Professional grade protein skimmers for the home aquarium. The most important things to consider when purchasing a protein skimmer are performance, reliability, and durability. The XFLO aquarium protein skimmer combines all the above to deliver one of the most innovative protein skimmers available today!

Don’t be fooled by sleek looks, gimmicky twists, or exaggerated needlewheel performance!

If a protein skimmer looks good and doesn’t perform, how good is it?

RK2 set the bar for protein skimmers in the public aquarium and aquaculture industries and has been the industry standard for over 25 years. Now you too can use what the professionals use! Let’s take a look at what makes the XFLO aquarium protein skimmer stand out from the ever varying protein skimmer designs in today’s market.

| Model | Tank size | Air input | Dwell time | Flow rate | Air draw |

|---|---|---|---|---|---|

| XF6-2.5 | 750-1500L | Venturi | 1 minute | 7.5lpm/450lph | 170lph-280lph |

| XF6-3.5 | 1500-2600L | Venturi | 1 minute | 11lpm/660lph | 340lph-450lph |

From materials, to research and testing, RK2’s XFLO skimmer was developed and designed with a higher standard in mind.

XFLO is made from the highest quality materials available. Our moulded bases are made from High Density Polyethylene

(HDPE) that doesn’t require gluing or bonding to fabricate. The reaction chamber is made from a single section of acrylic tube. The riser cone, collection cup, and collection cup lid are made from nearly non-breakable polycarbonate material and our Mazzei Air Injector (Venturi model only) is made from highly durable ozone resistant Kynar. This guarantees it will not break down when exposed to ozone.

XFLO has been tested and designed to run at specific levels of air injection. Don’t believe that the more air/bubbles you inject the better the skimmer will perform. The concept of increasing air flow while increasing contact time is scientifically impossible. Too much air, and the reaction chamber only fills with foam, which displaces water and decreases bubble contact time with “dirty” water, along with the true tank turnover rate.

RK2 Systems, Inc., the parent company of XFLO, has been the industry standard for over 25 years in the public aquarium/zoo sectors. We’ve taken their knowledge and applied it to making a protein skimmer designed for the home aquarium.

Made in the USA!

XFLO Skimmers are designed and manufactured in the USA with the highest-quality materials in the industry.