Welcome all to our first instalment of many of our information series. We hope to provide you with information, design recommendations and general operational guidelines to help you get more out of your Aquaculture facilities.

Technology evolves at a rapid pace in the Aquaculture Industry, and MBBR’s are no exception.

MBBR’s or Moving bed biological reactors are like a fluidised sand filters but use aeration to fludise floating plastic media, reducing pumping requirements associated with fluid beds, they can be effectively operated under gravity greatly reducing costs.

Add them to an existing system on a pumped loop, bury them in the ground to take advantage of gravity or partition off an area in your sump and expand your filtration capacity, MBBR’s are flexible, low initial and low ongoing cost, remove CO2 while adding oxygen and simultaneousdly removing ammonia and nitrite and are very user friendly and easy to construct.

They have become a mainstay for biological filtration in RAS, but designing them correctly from the start, or optimising an ageing MBBR biofilter, needs careful planning and consideration.

In this instalment we aim to give you some ideas, information and options to improve your existing MBBR, and provide some tips and design guidelines for upcoming installations you may have.

Below we will cover:

- Dwell times

- Mixing, velocity and aeration technology

- DO levels and its impact on nitrification

- BOD levels and its impact on nitrification

- Media choice, nitrification capacity and boosting your reactors performance with media upgrades

- Biological Augmentation

Dwell Time

MBBR’s are reliant on a range of parameters to ensure they operate at peak performance, and arguably the biggest is dwell time. Dwell time is the amount of time the water spends in reactor exposed the media carriers for the removal of ammonia and nitrite.

The general dwell time range for an MBBR falls between 4 minutes to 12 minutes with higher dwell times resulting in higher percentage removals of ammonia per pass. This in turn results in lower TAN levels going back to the tanks and lower residual TAN levels in the tank itself.

That not to say the water cant spend longer in the biofilter under higher dwell times, but this requires a larger reactor volume (or slower flow rates through the system which may negatively impact water quality) and depending on the aeration system, might result in lower DO levels due to a higher ammonia and nitrite removal rate.

In systems operating on a lower residual TAN effluent, or particularly in a cold water system, the dwell time might naturally be over 10 minutes due to a reduction in bacterial metabolism, or larger reactor volumes to accommodate more media. Lower TAN levels on the outlet of the MBBR do result in a larger MBBR, but also decrease in tank residuals and allow for better water quality and fish performance.

The increase in capital cost and operational costs are offset by better water quality and growth and better overall product.

The Key with dwell time is balance

Rule of thumb:

Warm water systems

Aim for 7-10 minutes dwell time

(this will almost always occur at TAN residuals of 0.25-0.5mg/L)

Cold water systems

Aim for 10 minutes plus

(due to reductions of 20-50% in nitrification at temps from 20-13 degrees Celsius, this increase in dwell time also almost always occurs, and lower TAN residuals should be standard i.e. nothing over 0.5mg/L)

There are exceptions of course, and ways you can adjust for lower dwell times, but higher dwell with lower TAN residuals on the MBBR outlet is best practice.

Mixing, Velocity and aeration technology

This is specifically referring to the aeration, mixing and movement within the reactor itself. The type and level of mixing, and localised velocity determine the overall performance of the media in regards to biofilm thickness and self cleaning ability. It also impacts distribution of ammonia and nitrite through the reactor and impacts removal rates.

Optimised mixing is incredibly important and should not be mistaken for turbulence. Turbulence in a reactor doesn’t necessarily equate to good mixing and sufficient localised increases in velocity for media cleaning and biofilm control.

Firstly – DITCH THE DRILLED PIPE

Drilled pipe is old tech, used primarily in wastewater systems where blocking was an issue, but even WWTP’s have moved to membrane diffusers for aeration basins and MBBR’s. Drilled pipe is incredibly heavy on air volume, has a low (to almost non existent ) oxygen transfer rate and is inferior in producing localised increases in velocity which promote shearing and cleaning of the carrier elements. Large bubbles from drilled pipe displace water rather than move water, which while a certain amount of media mixing is achieved, it is far inferior to diffused aeration.

Large “slug” flow in a pipe can displace and drag a certain amount of water with it effectively as it has walls to contain the water and the air bubble and move it in one direction, in an open reactor this simply doesn’t happen. Diffused aeration in airlift tubes also works far better compared to slug flow.

Diffused aeration moves huge amounts of water in its bubble plume, the plume almost creates its own pipe. One single diffuser assembly can move thousands of litres of water per minute and along with it, vast amounts of media.

The resulting localised increase in velocity in the bubble plume and the huge volume of water and media moved in diffused aeration systems achieves improved cleaning of the media and mixing of the reactor.

You will see in the below videos the flow and consequent circular flow pattern and suction of the media and water by the bubble plume from bottom to top.

Think of the bubble plume from the diffused aeration as the vehicle transporting the media and water around the reactor, rather than a large bubbles acting like a bulldozer simply pushing media and water out of its way.

The added benefit of diffused aeration and one that cannot be overlooked is oxygen transfer. There is a direct correlation between oxygen levels in the MBBR and nitrification per m2 of surface area. The more oxygen present, the higher potential nitrification rate you can achieve (this is also media dependent, more on this later).

In a nutshell, by using diffused air we:

- Get a far greater oxygen transfer (we can even calculate how much oxygen is added and how much oxygen is required to nitrify a given level of ammonia to nitrate to determine media and oxygen requirements)

- Use 30-35% less air – less air means less friction loss in plumbing, meaning you need a significantly smaller blower, sometimes more than a 50% reduction in energy consumption

- Increased cleaning and nitrification rates and increased DO levels on the outlet of the MBBR (reducing oxygen requirements overall)

- You can use a diffuser assembly that can be retrieved for maintenance and replacement

- You add oxygen directly where it is needed, the biofilm.

Generally speaking in a diffused aeration system we use either membrane diffusers or specifically designed self weighted but retrievable colorite diffusers.

Membrane diffusers are fixed in place and if they are damaged require either a diver to enter the filter or a complete shutdown of the filter to repair, they do however resist blocking which can be a great advantage in systems with higher solids loads.

Our retrievable Colorite diffuser assemblies are self weighted and come mounted on a base that gets them up off the bottom of the filter, this increases water draw from bottom to top, and also allows the units to be easily retrieved for maintenance or replacement, meaning no more filter shut downs.

Cleaning is also simple with a scourer pad or rubber glove, but turbulence in the reactor and contact with the media usuaslly keep the diffusers quite clean.

Colorite aerotube also has a significantly higher Oxygen transfer than membrane diffusers and a far lower pressure loss. Whats not to like!

You can see in the small clear filter below the process of water suction and media movement taking place.

In this filter there is a diffuser along the back of the filter, and a diffuser in the right hand end of the filter (clearing the screen of emdia).

Yyou can see two distinct zones of circulation, one moving from on end of the filter to the other, facilitated by the diffuser along the width of the filter and the screen, and the other from back to front facilitated by the diffuser placed along the back of the biofilter chamber.

You will also see the junction where they meet half way down the length of the filter and where one flow pattern is overcome by the other.

The vast quantity of water and media being moved away from and simultaneously towards the diffuser assembly’s location demonstrates the power of the diffused aeration system in moving the media and water within the reactor.

In the next video with the larger test pool is our prototype MBBR diffusers, there are a few things to note here.

- Notice the bubble plume shape between the left diffuser (flat on the floor) and the right diffuser (elevated of the floor), the right diffuser assemblies bubble columns are more dense, less “stretched” and as a result pull more water with them.

- If you look carefully, you can see particles being drawn towards the diffusers from quite some distance away indicating the vast suction and movement of water that diffused aeration achieves.

The last 2 videos are installations, the video with the white and black media is a NEW MBBR, this is a 4.5m3 media volume with 4 of the prototype diffusers in it, each running at 150LPM each. As you can see, the media and water movement with such a low amount of air flow and the resulting mixing in a new biofilter (where media usually cakes together for a period of time) is again demonstrating how effective diffused aeration is in mixing the media and water, and drawing water and media from the surface down to the bottom.

The second video is using our new generation MBBR diffuser, this filter features 11m3 of media again is using virgin brand new media, the pumps had only just been turned on. This was also the first commercial MBBR application to use the new K+ media

DO Levels

This is a pretty simple one, keep DO levels at least above 4ppm to get better nitrification.

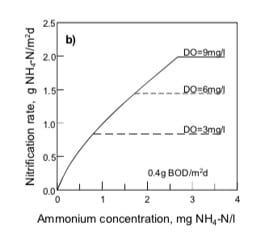

As you can see from the included graph (Odegaard 2006), an ammonia

concentration of 1.5ppm at a DO level of 3ppm will result in a

nitrification rate of under 1gm of NH4 per m2 per day, increase DO

levels to 6ppm and you now have a potential 60% increase to 1.5gm’s NH4

per m2 per day.

This is based on a BOD level of 0.4gm BOD/m2/day (more on BOD next)

Diffused aeration as covered above, allows you to increased your DO levels in the MBBR directly where its needed, the biofilm.

BOD Levels

Biological Oxygen Demand, or BOD, is everything that adds to the oxygen load in a system.

On top of Ammonia conversion and fish respiration, this is made up of suspended solids, solids in general, dissolved wastes and heterotrophic bacteria.

Mechanical filtration plays the major role in reduction of BOD, and having effective mechanical filtration is key to controlling BOD and water quality in general.

A very effective way to reduce BOD is a Foam Fractionator, and when ozone is applied, both he foam fractionator and the wider system as a whole, BOD can be reduced to almost insignificant levels.

This is why the application of ozone can increase your carrying capacity, as it 1. Directly increases nitrification through reduction of BOD and 2. Helps your mechanical filtration as a whole to function better, removing smaller particles and background levels of heterotopic bacteria, reducing oxygen demand on the system, reducing hetertroph counts in the biofilm on ther media in the MBBR and allowing more oxygen and surface area for the nitrifiers to utilise.

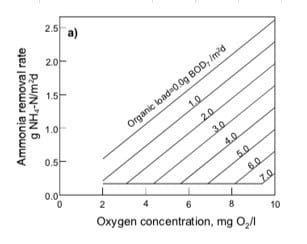

You can see from the graph t the right (Odegaard 2006) along with using the data from the previous graph of oxygen influence that there is a direct and quite severe influence of BOD on nitrification that despite elevated oxygen levels can have a sever impact on your MBBR’s ability to process nitrogenous waste.

Reducing BOD is a very effective way to increase your nitrification capacity.

Media Choice

Media choice is a big deal. It determines overall nitrification rates, its shape determines how the aeration system needs to be applied, and with new technology and engineering being applied to the design and production of MMBR media, it now has higher surface areas than ever before and through several augmentations, has shown faster maturation rates.

Pure Aquatics made the decision over a year ago to move away from cheaper mass produced media types as the consistency of product and surface area test data was highly variable.

Advertised verses measured surface areas differed dramatically, and no data on total VS protected surface areas could be supplied.

It is protected surface area that is important to an MBBR.

The surface area on the outside of the media, although it can achieve some nitrification, is the subject of such violent collisions that it cannot really be used or relied upon to include in the overall Volumetric TAN reduction rate capability of the media.

It helps to consider the nitrification capacity of the outside of MBBR media to be similar to that of the nitrification capacity of a fluidised sand filter.

Purely on surface area calculations alone, fluid bed filters SHOULD be able to nitrify many times more ammonia than they do, but the numbers don’t add up and are far less than expected, why?

The answer is that the outside of the sand is where the biofilm is, there is no protected surface area. Sand is incredibly abrasive, and as there is no internal structure to a sand grain (typically), it is the outside surface area only that is available to the bacteria to colonise.

The incredibly violent environment inside a fluid bed filter (from the perspective of a bacteria occupying a grain of sand anyway) is such that the nitrification rate of the fluidised sand filter is effected so dramatically because of constant violent removal of bacteria from the sand grains surface.

The saving grace is the surface area is so vast that the reduction in TAN removal is overcome by the shear massive surface area of the sand (sometimes in excess of 20,000m2/m3 depending on the sand grade chosen).

It is this violent environment that is the same in an MBBR as in a fluid bed which means outside surface area is simply not reliable to consider in TAN removal calculations in a MBBR. especially given a much lower overall surface area to volume ratio, the %percentage of surface area on the outside of the media is a much smaller percentage overall.

Through the use of quality, engineered and 3rd party measured MBBR media carrier elements we can get accurate and reliable numbers on Protected vs total surface area to perform reliable calculations to determine biofilter sizes.

This is why K+ media from Evolution Aqua and Hel-X flake biocarriers are so realiable to use when making biofilter calculations, as they have measured guaranteed surface areas and verifiable TAN removal rates.

Furthermore, based on surface area, the price per m3 is actually either the same or cheaper than other media choices out of Asia with unknown total vs protected surface area values, and results in less biofilter media being needed, which effects aeration size, reactor size and overall cost.

The good thing is that if you have a biofilter already, you don’t need to replace all the media to boost your nitrification rates.

Due to Hel-X flakes design and porosity it all but eliminates exposed surface area, it boasts a massive surface area of 5,500m2/m3, in a conventional moving bed, using a media with a surface area of 1000m2/m3 of protected surface area at a 50% fill rate, you can increase your fill rate to 60% (the maximum recommended fill rate for an MBBR) and with this small addition, DOUBLE your nitrification capacity.

If your media is lower in surface area that 1000m2/m3, then the effect is even more dramatic.

Biological Augmentation

Let me begin by saying, all nitrifying bacteria are not created equally and, by the same token, if you add strains to start up your moving bed to begin with, you will likely not have these same strains months or years down the track as strains die, mutate and get outcompeted by other strains.

Having said this, the application of certain strains has proved incredibly beneficial to our biofilter maturation procedures and our customers overall system health and performance.

Our NMI+, which stands for Nitrifying Microbial Isolates, has shown an interesting and novel side effect to both new and existing systems it is added to.

NMI+ along with its ability to nitrify ammonia and nitrite, startup biofilters quicker than ever before and handle incredibly high residual ammonia and nitrite levels in general, also performas AEROBIC denitrification in new an existing systems far faster than anerobic systems and without the need for organic carbon supplements than a methanol driven denitrification system does.

In fact is it so quick that there is no way an anerobic denitrification system could possibly have developed in that time, and with no addition of organic carbon to the system there is no way that it could fuel anerobic denitrification so quickly, a dissimilatory denitrification pathway (breaking nitrate down to nitrogen gas)

It has also been shown to work in freshwater systems without the ability to harvest biomass constantly through filtration such as foam fractionators, and so assimilatory denitrification (aerobic accumulation of nitrate into its own cell structure) has also been eliminated as a pathway, as although this is common practice in marine aquarium systems, the freshwater systems it has been trialled on have not had this type of biomass removal capability.

The advantages to the application of the strains contained in NMI+ are significant for a RAS system.

- Augmenting new and existing biofilters with a robust mix of nitrifiers

- No need for a dedicated denitrification system saving on CAPEX and OPEX

- No need for addition or organic carbon supplements to these filtration systems eliminating the need for methanol licenses, dangerous goods transport and dangerous goods handling

- Elimination of hydrogen sulfide production as the denitrification is occurring aerobically and removes the potential for sulfur reducing bacteria to proliferate in the system and in the denitrification system

- Persistent in the system and requires very low dose rates only periodically to maintain low nitrate levels

We are still field trialing this bacteria and testing strains to isolate the full potential of the biological augmentation for RAS systems, but we now have dozens of biofilter startups and additions to existing systems that show the same results, aggressive denitrification from the beginning and only low nitrate levels several months after the initial application.

If you would like to be involved in field trials please let us know.

thanks for sticking with us for this installment, MBBR design and operation is complex but it can be optimised with great effect whilst also saving you significant amounts of money and improving water quality and production.

Should you like to know more, see where your MBBR can be optimise or look into some mroe siginficant upgrades please do not hesitate to give us a call in the office or send us an email.

Until our next installment!

Gareth Barber

Design and systems technical support