Aeration and Oxygenation Products for Aquaculture and Wastewater.

Pure Aquatics custom designs and implements aeration and oxygen systems for Aquaculture and wastewater applications.

Some of the product we utilize are:

We offer customer design and friction loss sizing utilizing our purpose built air friction loss calculator.

Jet Blowers are advanced centrifugal blowers designed to operate at speeds up to 100,00 RPM–three times faster than conventional turbo blowers. Featuring a patented ultra-high-speed motor, Sprintex jet Blowers are smaller, lighter, and quieter than even the latest turbo models.

These blowers offer exceptional energy efficiency, require zero maintenance over extended periods, and incorporate intelligent control systems, setting new performance standards in industrial blower technology.

Techno Takatsuki was the first to create electromagnetic diaphragm air pumps with the launch of the Hiblow Diaphragm Air compressor series air pumps in 1967. Since that time they has produced over 12 million units and remain the leading innovator of this electromagnetic diaphragm technology.

HIBLOW advanced technology has been applied to create highly durable, high quality, low noise and power efficient solutions for an expanding range of technical applications in over 40 countries worldwide.

HIBLOW products can be found in a diverse array of industrial, medical, environmental and consumer related applications. Power efficiency and well-tested rugged reliability makes them ideal for many continuous use indoor and outdoor applications.

For over 60 years, HIBLOW has been recognized as a highly reliable supplier and innovative designer of air pumping technology. Customers include many of the worlds largest and well known companies such as Panasonic, Hitachi, and Sanyo.

The company has been certified to ISO-9001 standards since 1995. This certification was upgraded to ISO-9001:2000 in 2001. As part of our overall corporate commitment to saving our environment, we established an environmental management system under ISO-14001 for the continuous improvement in our impact on the environment.

HIBLOW DIAPHRAGM AIR COMPRESSOR

ESAM Side channel blowers – Italian built quality aeration equipment

The key benefits when purchasing an ESAM side channel blower is that you are using a product that is designed & manufactured with precision detail under the quality program of ISO 9001.

Manufactured in Parma Italy and warehoused in Melbourne Australia all ESAM units are tested rigorously. Our commitment is to ensure that with every side channel blower purchased ESAM are supporting this with a 5 Year Warranty.

Our product, if installed by a qualified technician is relatively maintenance free, reliable and environmentally safe to run continuously with maximum output.

ESAM Australia also stock spare parts & accessories and offer technical support where required.

Pure Aquatics offers quality Esam Side channel blowers and products, supported by thorough sizing calculations and ongoing customer support.

With ESAM and Pure Aquatics you can be sure your system will be sized and designed properly, and be supported by the best quality equipment on the market.

Who is ESAM?

Formed in Italy in the 1960s, ESAM leads the design and manufacture of high-quality side channel blowers and oil-free reciprocating compressors. Our commitment to our customers has always been to supply products of the highest possible quality, complemented by excellent service and support.

Our service and support is comprehensive and includes providing in-depth technical advice before a sale is made, ongoing parts sales and service, and the commitment to being ready to help you get the best from your product during its lifecycle.

Experience and knowledge

ESAM has designed and produced many important products for a range of customers. Our project work includes the design and manufacture of a compressor for NASA that weighed only 180 grams and built up 38 bar of pressure. Closer to earth, we also designed and produced bespoke side channel blowers for the Italian speed train ‘Pendolino’. These specially designed side channel blowers equalise cabin pressure when the trains enter tunnels at high speed. Every day, we are hard at work to ensure our customers benefit from our innovation and dedication to perfection.

GreenCo Side Channel blowers, produced by Zhejiang Greenco Industry Co Ltd was established in 2001, and are located in the South eastern Coast of Zhejiang. They have already become professionals in designing and manufacturing ring blowers and air compressors in China.

They have powerful technology, precise inspection devices and have introduced an advanced assembly line and equipment, imported and taken in advanced international technology for their production.

FLOWS FROM 50 – 2,500 M3/H

DELIVERY PRESSURES UP TO +1000 MBAR

VACUUM UP TO -800 MBAR

The Side Channel Blower principle allows oil-less and contactless compression of pumped gases, enabling a low maintenance, contaminant free pumping environment. Side Channel blowers are low in noise level alternative to PD blowers. There are many applications which require positive pressure air and suction.

QUALITY

They strictly practice the CE and ISO9001 quality standard in production to make us an enterprise of science and technology.

EFFICIENCY

Like all side channel blowers, GreenCo Side Channel blowers produce large volumes of air at relatively low pressure. Through GreenCo’s extensive research and development, we are able to offer a wide and extensive range of blowers.

Because of Pure Aquatics friction loss sizing programs and plumbing design experience, we are therefore able to offer an aeration system design utilising the most suitable blower for the application to offer the ultimate in efficiency.

FEATURES

Dynavac, the importers of Greenco offer the world’s most complete and up-to-date range of Side Channel blowers. Our family of blower ranges offer delivery flows of up to 2,500 m3 per hour and discharge pressures of up to 1000 mbar. The Dynavac family of side channel blowers includes the following ranges:

Colorite Aerotube diffuser tubing provides effective diffused aeration at a low cost due to its high porosity and low pressure loss. Just like normal diffusers, Colorite Aerotube diffuser tubing offers fine to medium sized bubbles that are ideal for aeration and degassing.

Why is Colorite Aerotube diffuser tubing so good? Compared to paddle wheels at only 0.9kg’s of oxygen per horsepower this represents significant increases in efficiency for aeration systems.

Because Colorite Aerotube has such a low pressure loss, it is perfect for use with side channel blowers and linear air compressors. For more information on the blowers and air pumps we sell please visit our aeration page.

– Anti fouling properties– Mixing and circulation of bottom water creating both horizontal and vertical mixing throughout the pond– De-stratification, equalizing temperature and dissolved oxygen– Oxygenation of bottom sediment in ponds due to high volume mixing– Directional flow in tanks and ponds with the use of airlifts and directional plates– Low energy costs compared to other aeration technologies– Reusable and long lifespan, easily cleaned– Available in a variety of configurations such as prefabricated diffusers, per meter, in grids and pre fabricated airlifts and diffuser rings– 3rd party validated oxygen transfer rate, OTE%’s and quality construction

– Small and Large volume airlifts for recirculating aquaculture systems– Airlifts and complete aeration systems for aquaculture ponds– In tank aeration and degassing– Aeration systems for recirculating aquaculture systems– Water storage aeration– Live seafood system aeration– Wastewater and remediation pond aeration– Biofloc

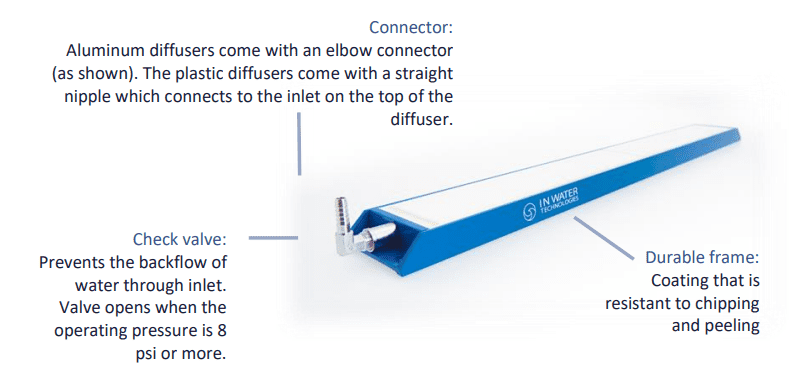

The InWater Micro Bubble Oxygen Diffusers are made from a high-quality ceramic designed for high-efficiency diffusion of oxygen into water. A micro-sized bubble pattern means that bubbles are suspended in the water for longer. The coating is resistant to chipping and peeling and has a proven record of long-term durability. The diffusers are available in either an aluminium frame for freshwater applications or a plastic frame for saltwater applications.

| Frame | Size | Weight | Flow Rate |

|---|---|---|---|

| Aluminium | 300mm | 1kg | 1-4LPM @ 21-35PSI |

| Aluminium | 600mm | 2kg | 2-8LPM @ 28-42 PSI |

| Plastic | 300mm | 1kg | 1-4LPM @ 21-35PSI |

| Plastic | 600mm | 2kg | 2-8LPM @ 28-42 PSI |

Although aeration and circulation are separate processes both can greatly affect pond dynamics and are important to prevent the natural aging of pond soil condition and water quality.

An effective management strategy includes both aeration and circulation. The benefits of such a system can help to extended the life of the pond, provide improved water quality and pond soil, uniform temperature and DO distribution from the surface to bottom, help reduce anoxic sediment layers, and improve habitat for production.

Applying mechanical aeration and circulation depends on a number of factors such as the type of application and the size and depth of the water body. The team at Pure Aquatics can help assist you to select right equipment for your application.

The Force 7.2 is a submersible aerator, which oxygenates by drawing in and dispersing air at depth, in the form of micronised bubbles.

The FORCE 7.2 is a compact, robust, but lightweight, easily handled aeration device with unrivalled performance characteristics. Being submersible in design, the unit can be positioned at depths of up to 15.0 metres below the water surface via the use of extension snorkels. The FORCE 7.2 can also be configured to mitigate stratification of water bodies by creating influencing currents at the surface or at depth, by pivoting the motor axis up to 35o above and below horizontal for specific applications.

| Supply Requirements (V) | Rated Power (HP) | Rated Power (kW) | Rated Current (A) | O2 Delivery Rate (m3 O2/Hr)* | O2 Delivery Rate (kg O2/Hr)* |

|---|---|---|---|---|---|

| 240 (Single Phase) | 1.5 | 1.1 | 7.5 | 3.3 | 2.4 |

| 415 (Three-Phase) | 1.5 | 1.1 | 3.2 | 3.3 | 2.4 |

The STORMIX 4.0 is a submersible aspiration aeration unit which provides aeration by drawing in and dispersing air, at depth, in the form of micronised bubbles.

Being submersible in design, the motor unit can be positioned at depths of up to 3.0 metres, via the use of extension snorkels. STORMIX can also be configured to mitigate stratification of waterbodies by creating influencing currents at the surface or at depth, by pivoting the motor axis up to 35o above and below horizontal, for specific applications.

| Supply Requirements (V) | Rated Power (HP) | Rated Power (kW) | Rated Current (A) | Oxygen Delivery Rate (m3 O2/Hr)* | Oxygen Delivery Rate (kg/Hr)* |

|---|---|---|---|---|---|

| 415 (Three-Phase) | 4.0 | 3.0 | 7.6 | 14.7 | 10.9 |

*At a standard 1.0m immersion depth with ‘Air’ Propeller

Water circulation is an effective strategy to mix high-oxygen surface waters with low-oxygen (anaerobic) bottom waters.

Designed to handle larger sized water bodies with a total water volume of greater than 10 megalitres the Rio Circulator maintains constant water movement between the waters surface and the bed aiding in mixing, destratification, circulation and aeration. The rotational operation of the large three-bladed propeller provides power through a 15:1 reduction gearbox, allowing it to rotate at 115 RPM.

The Rio Water Circulator is a heavy duty mechanical unit which is designed for continuous operation in both fresh and salt water environments. Because of its simple direct drive design, in general terms, the Rio Circulator has a very low maintenance requirements.

The Rio Circulator comes supplied with an Australian-sourced frame and float configuration and is installed via 3 x 4 mm stainless steel mooring cables shackled to static points on the water bodies bank. It can also be supplied as a motor only for a completely submerged installation, mounted on a structure or concrete slab where it is desirable to completely ‘hide’ the unit.

| Specifications | |

|---|---|

| Supply Requirements | 415 (Three-Phase) |

| Rated Power (HP) | 2.0 |

| Rated Power (KW) | 1.5 |

| Rated Current (A) | 4.3 |

| Propeller Rotational Speed (RPM) | 115 |

| Mixing Volume Capability (kL/Hr) | 25000 |

Water circulation is an effective strategy to mix high-oxygen surface waters with low-oxygen (anaerobic) bottom waters.

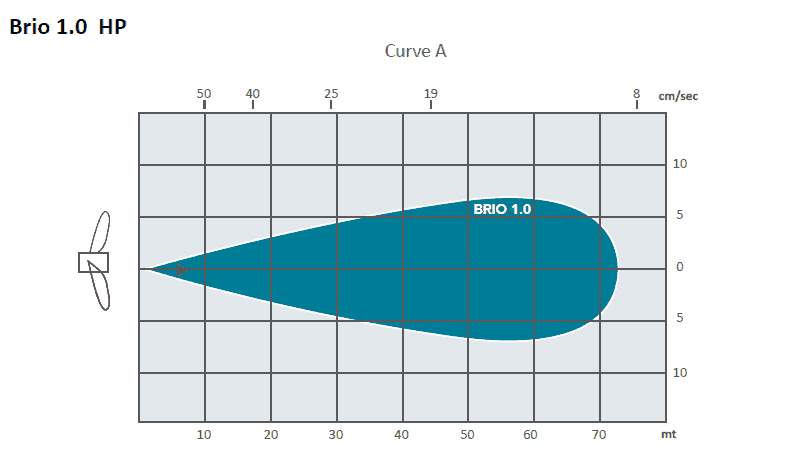

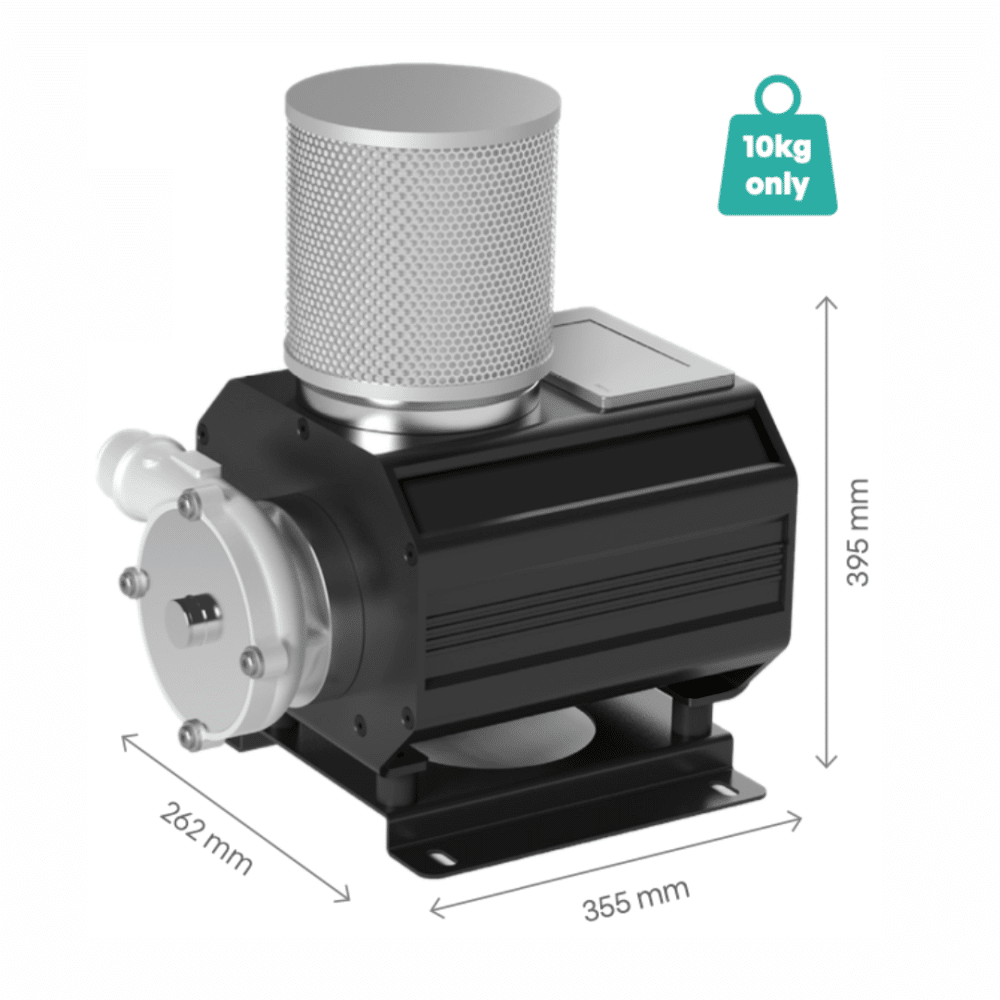

The Brio Circulator is a workhorse circulator that you can rely on.

The Brio Circulator is perfect for small to medium sized water bodies with a total volume of between 5 to 10 megalitres. The Brio Circulator maintains constant water movement between the waters surface and the bed aiding in mixing, destratification, circulation and aeration. The submersible motor unit provides direct drive to twin propellers (180mm in diameter) rotating at 1400 RPM.

The Brio Circulator is a heavy duty mechanical unit which is designed for continuous operation in both fresh and salt water environments. Because of its simple direct drive design, in general terms, the Brio Circulator has a very low maintenance requirements.

The Brio Circulator can be supplied with an easy to install lightweight floating design providing adjustable motor depth and orientation.

| Specifications | 240v Single Phase | 415v Three Phase |

|---|---|---|

| Rated Power (HP) | 1.0 | 1.0 |

| Rated Power (KW) | 1.2 | 1.2 |

| Rated Current (A) | 4.5 | 2.0 |

| Propeller Rotational Speed (RPM) | 1400 | 1400 |

| Mixing Volume Capability (kL/Hr) | 1200 | 1200 |